Home > Knowledge Base > Integrated Logistics Support

Introduction

Introduction

Integrated Logistics Support (ILS) is common use in the naval shipbuilding industry. It comprises the whole life-cycle of the vessel i.e. from the research phase up to the demolition of the vessel. As such it is the concern of the different sectors of the maritime industry:

- Designers

- Producers

- Users

Where these three functions are fulfilled by two or mere different companies interface problems are likely to occur.

In this paper ILS will be described from the point of view, of a producer, a shipyard, which has also a design capacity of its own. In that case ILS is the interface between producer and user i.e. between shipyard and Navy.

Why ILS?

ILS is demanded by a Navy; The way ILS is treated and the extent to which ILS is, performed differs from Navy to Navy, The reasons why ILS is demanded, by a Navy are based on the following characteristics of the vessel procured:

- The vessel is complicated. A lot of components and installations are 'one-off’s';

A lot of electronics are used, together with a high level of automation.

- The vessel requires a relatively high investment.

- The vessel has a long life-cycle (20-25 years).

- The vessel is of strategic value.

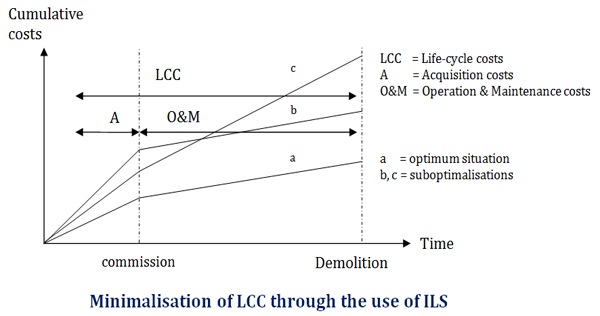

The purpose of ILS is to minimize the life-cycle costs of the vessel with a maximum of system effectivity (fig. 1).

Fig. 1 Minimalisation of LCC through the use of ILS

Because of the demand for ILS by a Navy, it seems obvious for the selected shipyard to assist the Navy with the ILS related to the naval craft in question.

The aim of this short review is to highlight the fact that a more cost effective ILS seems possible for a Navy by enlargening the scope of supply of a shipyard with the so called initial part of the ILS. To contract both the initial part of the ILS and the vessel to be built to a shipyard will most likely lead to an initial ILS of a higher quality with lower overall costs for the purchasing Navy.

Shipyards which depend on selling naval craft (especially for export but also to their domestic Navy) with in depth knowledge of ILS will be more competitive than those who don't possess this expertise. Thus they stand a better chance to survive in a market suffering from a (sustained) recession. Furthermore the shipyard, as the most likely main contractor, would also be the most obvious supplier of the initial ILS because as a systems integrator responsible for the total system, they are required to have the knowledge of the total product. Interface problems in distributing and combining information are more easily avoided.

What is ILS?

In general, seen from a producer side, ILS fulfils the same function as product support or service in other areas of industry like the aircraft-industry or the computer-industry. It has to ensure that the product, in this case a ship, can be operated and maintained throughout the utilization phase to the satisfaction of the user.

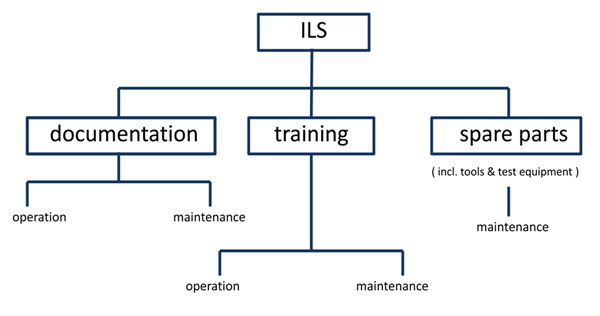

ILS is characterised by 2 elements:

a. transfer of knowledge, performed by the ILS-elements documentation and training.

b. support, performed by the ILS-element spare parts.

In its outer form ILS is an iterative process. To achieve optimal cost-effectiveness ILS should be integrated in the design process of the vessel, preventing 'penny-wise pound foolish' decisions.

To have the best end-results ILS has to be realized close cooperation between the, Navy, shipyard and its suppliers.

From a practical point of view ILS can be seen as a system to prevent failures. Therefore it can reduce guarantee-claims for the shipyard and enlargen the satisfaction of Navy regarding- its investment. ILS as such has a mutual benefit for both shipyard an Navy concerned.

ILS is based on the following information:

- Operational requirements.

- Maintenance concept.

The Navy is to provide this information which comprises:

- Mission profiles of the vessel: mission duration, operational readiness, usage intensity of the equipment, permitted downtime for maintenance etc.

- Operational area of the vessel, environmental conditions.

- Maintenance philosophy: scope of preventive maintenance, level of repair analysis, maintenance frequencies; maintenance, facilities spare parts, supply support; stock control etc.

The shipyard as a systems integrator has to provide system Information which has to comply with the requirements of the Navy; The suppliers have to provide information related to the equipment they deliver to the shipyard.

Whenever a Navy is notable to specify ILS requirements: in detail, but, nevertheless has a demand for it, the shipyard should be able to propose ILS-requirements to that Navy.

The costs of ILS?

The total ILS can be split into two parts:

- The initial part, to be delivered together with the vessel.

- The after sales part, during the exploitation phase of the vessel.

Normally the initial part of the ILS is together with the vessel itself, contracted to the shipyard where the vessel will be built, or from third parties.

The initial part of the ILS is necessary to be able to integrate the vessel together with its ILS-elements into the existing system of the Navy organisation. As such it is also in the interest of the shipyard that this integration will take place to the full satisfaction of the Navy. The initial part of the ILS can be influenced (reducing costs) by the shipyard. The costs of the after sales part of the ILS depend strongly on the Navy organisation and operational profiles of the vessel and are therefore the responsibility of the Navy itself.

Roughly spoken the costs of the procurement of the initial ILS constitute about 10% of the ship's procurement costs.

This indication has to be handled with care because it depends on the scope of supply within the ILS i.e. the depth of the ILS. In general, the scope of supply of the ILS is divided into 3 levels (defined in the maintenance concept):

1. Organisational Level; this comprises the ILS to the on-board level and deals with operation and on-board maintenance, carried out by the crew of the vessel.

The ILS comprises:

- Documentation for operation and on-board maintenance (system and equipment).

- Training for operation and on-board maintenance (system and equipment).

- Spare parts, tools and test equipment to carry out the on-board maintenance.

2. Intermediate Level; this comprises the ILS to the base level and deals with base maintenance of the ship; carried out by base maintainers. It comprises documentation, training, spare parts, tools and test equipment to be able to carry out the base maintenance.

3. Depot Level; this comprises the ILS to depot level and deals with depot maintenance of the ship (i.e. major overhaul of the ship or repair of equipment at the manufacturer's plant).

The after sales' part of: the ILS is normally the responsibility of the Navy. Costs.-are spread out over the exploitation phase and can go up to several times the amount of the initial Investment in the vessel. One of the main advantages of ILS is minimalisation of these costs.

Conclusion

From the shipyard point of view ILS is often considered as a downstream activity; as a necessary evil. However, for the user (e.g. Navy) ILS is essential, namely the tool to operate and maintain its investments as cost effectiveIy as possible.

The need for ILS will only increase because of increase in complexity of the hardware and therefore in procurement costs of a naval vessel on the one hand, and the need for Navies to spend the available budgets more effectively on the other. Total systems' operational envelope can only be economically controlled by means of a well balanced ILS from the start.

A shipyard with its aim at the future therefore has to assist Navies in reaching these goals. A consequence is an investment in an ILS-organisation with a capability able to meet the lLS-requirements of a Navy.

By:

ir. M.M.R. Kuijer

Page 2 of 2 1 2

GSD Menu

Product&Service

- Software Development

Systems analysis, systems design, Intranet and Internet software development. - GILS

Giant System Design Integrated Logistics Support Web Application. - Accounting System

Accounting, budgeting, financial, purchasing and inventory control system.

Knowledge Base

- Maintenance Management

Maintenance plan, maintenance concept and maintenance levels. - ILS

Integrated Logistics Support.

Number of visitors